100,000 PSI Yield Strength and 110,000 PSI Tensile Strength vs 36,000 PSI Yield Strength on standard hoppers!

100,000 PSI Yield Strength and 110,000 PSI Tensile Strength vs 36,000 PSI Yield Strength on standard hoppers!

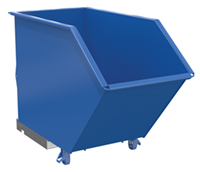

High Strength hoppers are designed to provide years of dependable service in the toughest applications- heavy scrap of all types (metal, glass, stone, etc.) machine shops, fabrication, glass industries, commercial construction and hundreds more!

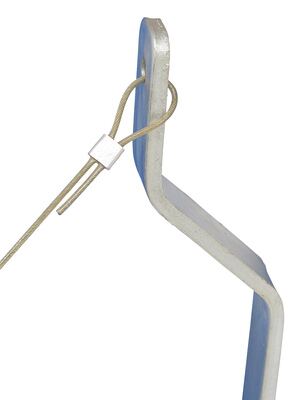

H-Style high strength hoppers are made with material that provides greater impact resistance to dents and punctures, while still have all the best features of standard H-Style hoppers! They feature a full 90 degree dump angle with a cushioned rubber bumper stop. The low profile design is essential for convenient loading. Dumping with a fork truck is quick and simple. A cable is pulled from the seat of the fork truck to dump the hopper. The unit returns to an upright and locked position when lowered to the ground. The included safety restraint/chain must be securely attached to the lift truck without slack. 22" L usable fork pockets measure 7"W x 2"H. Formed base thickness is 1/4". Blue baked-in powder-coated toughness with a galvanized base. Models H-25 may be stacked with H-50 models. Never stack hoppers more than 3 high. Must be attached to fork truck when dumping. Minimize fatigue and injury during loading! The low profile front edge provides an unobstructed path for item placement!

D-Style high strength self-dumping steel Hopper with bumper release automatically dumps when bumper release contacts the front of the dumpster. Also includes a cable that may be operated from the seat of the fork truck to manually dump the hopper. Hopper is stackable if you stack the top hopper turned ninety (90) degrees from the bottom. Self-dumping hoppers facilitate compliance with OSHA general industry rule 29 CFR 1910.178(m)(5)(iii) by allowing lift truck operators to remain at the controls of their truck throughout the dumping process. Length dimension is measured at top of chute.

- High-Strength material provides greater impact resistance

- Resists and dents and punctures from dropped materials

- Great for use in foundry environments

- Promotes extended product life

Check out our Standard H Series and D Series Hoppers!

Check out our Standard H Series and D Series Hoppers!

Caster Options |

Caster Options |  Optional Lids

Optional Lids